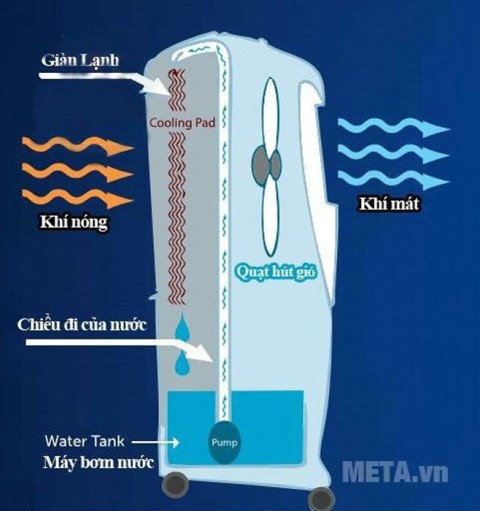

Air conditioner copper pipe is a gas pipe made of copper, which is responsible for circulating gas from the evaporator to the condenser and vice versa. This copper pipe directly affects the cooling capacity and durability of the machine. Therefore, if the standard length of the air conditioner copper pipe is followed, the machine will operate more stably and safely.

Why is the minimum length of air conditioner copper pipe 3m?

If the air conditioner copper pipe is less than 3m long, the air conditioner's gas circulation will pass through the block faster, the amount of gas that is not evaporated will overflow into the block. This causes the air conditioner block to work continuously at high intensity, so it is easily overloaded, quickly damaged and shortened in life.

In addition, the block operates continuously and vibrates strongly, causing the air conditioner to make loud noises, affecting everyone's daily life.

Suitable length of air conditioner copper pipe

The minimum length of the air conditioner copper pipe is about 3m, the maximum is about 15m or for large capacity types it is 20m.

The average length for the machine to operate best is about 3 - 7m. If the copper pipe is too long, the air conditioner will cool slowly, or not cool at all.

Other standards when installing copper pipes for air conditioners

Copper pipes for air conditioners today mainly use 2 types: pipes from the condenser to the evaporator (inlet pipe) with smaller size and pipes from the evaporator to the condenser (outlet pipe).

- For 1 HP machine (~ 9000 BTU): the inlet pipe has an outer diameter of 6mm and the outlet pipe is 10mm.

- For 1.5 HP (~ 12000 BTU) machines: the inlet pipe has an outer diameter of 6mm and the outlet pipe is 10mm or 12mm.

- For 2 HP (~ 18000 BTU) machines: the inlet pipe has an outer diameter of 6mm and the outlet pipe is 12mm.

- For 2.5 HP (~ 24000 BTU) machines: the inlet pipe has an outer diameter of 6mm and the outlet pipe is 16mm.